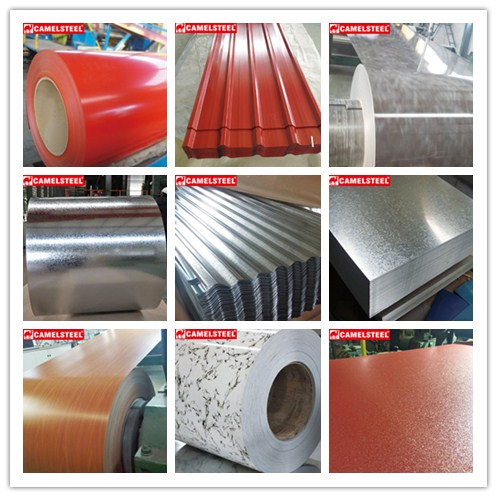

1. Hot dip galvanized steel substrate.

Products that coated by organic coating on the hot galvanized steel is color coated galvanized steel sheet. Besides the protective effect of metallic zinc, the organic coating layer also has insulating, protective and rust-protection roles and the service time of the layer is longer than that of hot galvanized sheet. The zinc content in hot galvanized steel substrate is 180 g/m2 (two sides) in general. The maximum zinc content in hot galvanized steel substrate used in the external of buildings is 275 g/m2.

2. Hot dip alu-zinc steel substrate.

It takes hot dip alu-zinc steel substrate (55%Al-Zn) as steel substrate. Generally, the aluminum and zinc content is 150 g/m2(two sides). The corrosion resistance of hot dip aluminum-zinc plate is 2-5 times of that of hot dip galvanized plate and the ability to reflect heat and light of the former is 2 times of that of the later. Continuous or interval use under 490℃ can not cause serious oxidation or oxide skin. Thus it is the ideal building material for energy saving.

Both these two color coated steel coil based on hot dip galvanized sheet or galvalume sheet are no problem for CAMELSTEEL. Any demands about them,please feel free to contact with us.