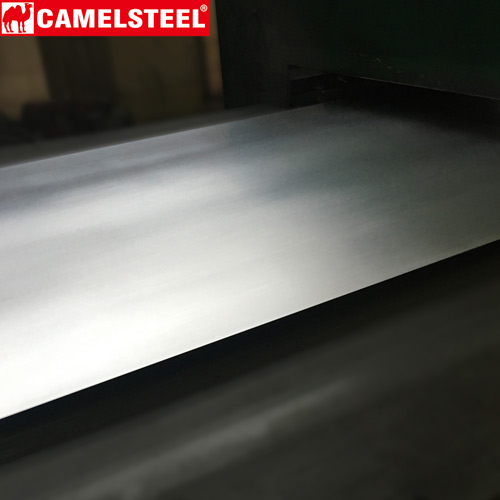

The color coated steel coating can achieve a certain degree of anti-corrosion effect. Users can use the coating to isolate the outside corrosive substances. But because from the microscopic point of view, the color coated steel coating itself still have some pores. So a small amount of the air vapor will invade to the coating, resulting in coating foam, and may also cause the color coated steel coating layer off.

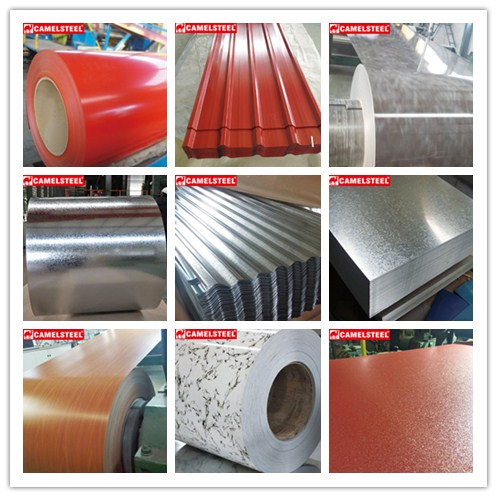

The color coated steel products usually adopt surface cleaning and chemical conversion film treatment on the basis of galvanized, and then coat two layers of dense organic coating as bottom paint and top paint to be the protective barrier. It effectively prevents the immersion of water molecules and corrosive media, also has the ability to against the destruction of ultraviolet light and other natural light ability.

For the same color coated steel coating thickness, the twice coating is denser than the one coating. The color coated steel coil in CAMELSTEEL adopts the double painting double drying crafts, relatively speaking, it will have better corrosion resistance and longer service life. The color coated steel coating thickness is required to achieve a specified film thickness to obtain a dense shielded coating, then to reduce the permeability, oxygen permeability and prevent the coating corrosion.

Leave A Comment