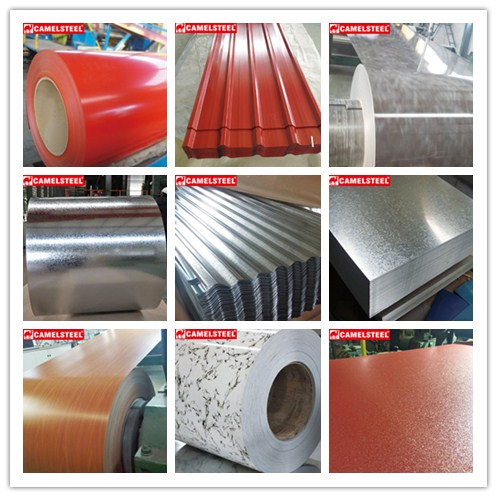

In the color coated steel coil selection, the most important are generally the substrate and top paint of color coated steel coil.

The domestic basic zinc coating generally have: double side zinc coating 100 g/square, zinc coating 120 g/square, zinc coating 140 g/square etc., and the highest zinc coating can up to 280 g/square.

If you want to use better, you can use the color coated steel coil with galvalume substrate, the highest galvalume coating can reach 220 g/ square.

Secondly is the top paint of color coated steel coil, it includes top paint type, top paint thickness and baking time. The top paint type can be divided into ordinary PE polyester top paint, PVDF fluorocarbon resin top paint and SMP polyester top paint etc.. No matter what kind of top paint type, to achieve the quality requirements must meet a certain coating thickness. In CAMELSTEEL, our regular paint coating is top paint 15-25 μm, back paint 7-25 μm. Only the enough top paint thickness can sufficiently resist the erosion of the external environment.

As for baking time, when the top paint type is very good, and the thickness is reached, if the baking time is not enough, the top paint is very easy to produce powder and fall off.

Leave A Comment