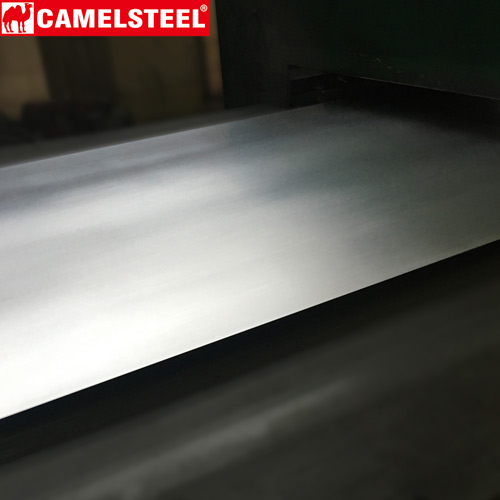

One common surface defect of the galvanized coils and the handing method is passivation spot ( passivation yellow edge).

1. The passivation squeeze roller distortion or roller surface disrepair. It will cause passivation spot.

2. The two sides tuyere have a long distance with the steel edge. So the pressure of the squeeze roller will be smaller, and the strip steel will deviate the center. Then it will cause the passivation yellow edge.

3. After the stop or when the squeeze roller is not working properly, it forms the passivation drying in the surface of the passivation solution . And it will form the passivation drying bellows or form the passivation yellow marks.

4. The temperature of passivation fluid is too high, and the passivation film is too heavy. Therefore, the steel board becomes yellow.

5. The temperature of steel in passivation gutter is too higher.