Galvanized Principle. In the plating tank of galvanized solution, using the to be plated parts after cleaning and special pretreatment as a cathode, and the plating metal as anode. The poles are connected to the positive and negative terminals of the DC power supply respectively.

The zinc plating solution is composed of an aqueous solution containing plating metal compound, conductive salt, buffer agent, pH modifier and an additive. CAMELSTEEL learned at the factory technical staff that, after electrifying, the metal ions in galvanized liquid will move to the cathode to form cladding material on the effects of potential difference.

The metal on anode forms to metal ion and then enter into the zinc plating solution, in order to keep the concentration of the coated metal ions. Such as chromeplate, it adopts the lead, lead antimony alloy to form the insoluble anode, it only plays the role of transmit electrons and conduction current. When galvanizing, the quality of the anode material, the composition of the galvanized liquid, temperature, current density, power time, stirring strength, precipitation of impurities, power waveforms and so will affect the quality of the coating, and need to control timely.

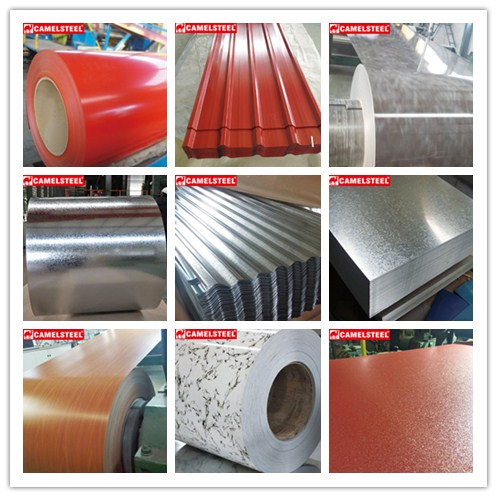

Galvanized steel sheet can be used bare, prepainted or postpainted. It is easy to fabricate and stamp and is used for applications that require corrosion resistance.

Leave A Comment