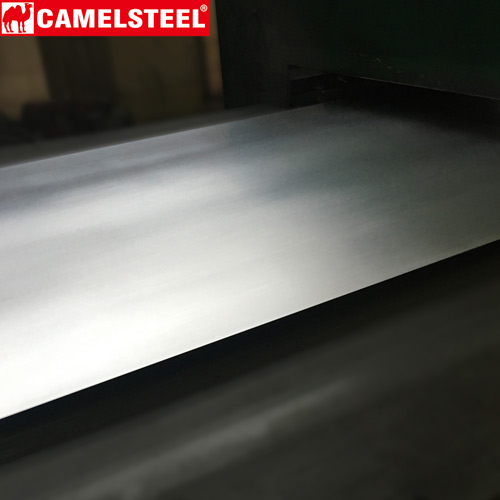

Galvanized steel coil is covered with the zinc layer on the steel plates. The electrode potential of metal zinc is higher than that of iron steel. During the atmosphere and erosion environment, the galvanized steel coil zinc layer react with the environment to form the passivative film to avoid erosion. And galvanized steel coil zinc layer prolong the service life of steel sheets. Therefore, CAMELSTEEL reminds people that, if the zinc coating is not fixed with the steel plate surface firmly, and the galvanized steel coil zinc layer is miss, its service life will be shorten.

Now, here will analyse some of the causes of galvanized steel coil zinc layer fall off.

1. The substrate surface of galvanized steel coil is not cleaned totally. The remnant residue and emulsification grease can not clean up after the reduction furnace, and it affects the adhesive power of zinc.

2. There is ferric oxide layer on the substrate, and the oxide can not be restore which affect the zinc layers’ adhesiveness and lead to the zinc layers fall off.

3. There is little AL in the alloy layer and it does not produce the suitable alloy which could decide the zinc layers adhesiveness.

4. The steel plate in the annealing furnace stays too long, and the surface temperature is too high. When they are put into the zinc pot, the temperature of zinc liquid starts to raise.

Leave A Comment