Hot dipped galvalume steel coil is produced with cold rolled steel plates under hip-dipping coating process. The cladding layer contains 55% aluminum, 43.4% zinc and 1.6% silicon. The advantages are as follows:

Super strong corrosion resistance: Its corrosion resistance is 6-8 times of that of common galvanized plate. Thus it will not rust in various environments for 20 years.

High temperature oxidation resistance: It will not suffer discoloring or deformation on constant use under 315℃.

High heat reflectivity: Its high heat reflectivity is over 75%. Unpainted galvalume steel plate can serve as roof and panel so as to save energy.

Easiness in processing: Processes include stamping, cutting and buckling.

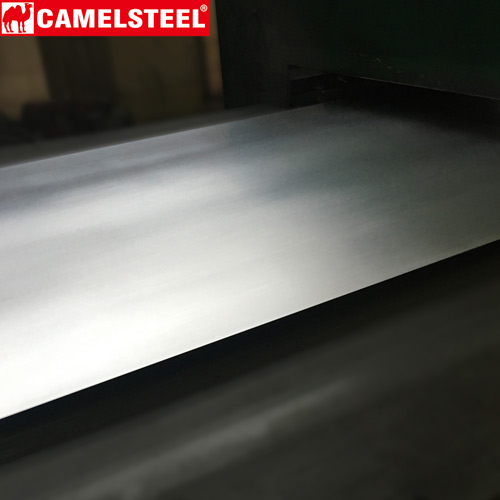

Beautiful appearance: Silver snowflake pattern looks beautiful. Thus it can be used directly with no need for painting.

Regular specification of hot dipped galvalume steel coi in CAMELSTEEL: Thickness: 0.16-0.7 mm, Width: 600-1250 mm, Alu-zinc coating: Alu-zinc 40-150 g/sm, Spangle: Regular Coil, Weight: 3-8 mts

Length: Coil or as Customers’ requirement

Depending on excellent corrosion resistance, the hot dipped galvalume steel coil has been widely used around the world replacing galvanized steel plate. Meanwhile, more and more customers have ordered alu-zinc coated steel sheet from CAMELSTEEL. We believe that we will go further in virtue of excellent quality and service in the future.