Hot galvanizing refers to the process in which parts are put into bath of molten zinc for a while after oil removal, pickling, drying, followed by being taken out. Cold galvanizing is also called electro-galvanizing, referring to the process of putting parts into zinc salt solution after oil removal and acid pickling, then connecting solution to the negative electrode of electrolysis machine, putting zinc plate in the opposite of parts and connecting it into the positive electrode and switching on power. With electric current moving directionally from positive electrode to negative electrode, a zinc layer will deposit on parts.

Difference in looks: electro-galvanizing is smooth and bight. Electro-layer adopting iridescent passivation process is mainly yellow green, looking colorful. Electro-layer adopting white passivation process presents bluish-white or white showing green ray. This electro-layer looks colorful when there is a certain angle between it and sunshine. Angle and edge parts of complex parts are easily to cause electricity burning and present gloomy. Zinc layer in these parts is thick. Electricity dead angle is easily formed in internal corner, thus forming undercurrent gloomy zone. The zinc layer in these parts is thin. Parts see no list edge or caking.

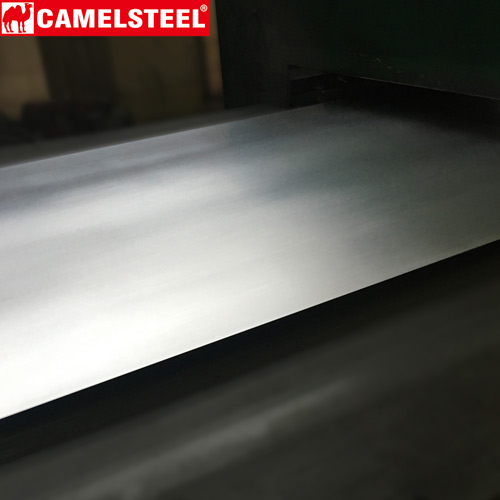

Hot galvanizing is slightly coarser than electro-galvanizing and looks white. It is easy to generate water wave and a few drop tumor, especially in one end of parts. Yet, the zinc layer of hot-dip galvanizing is dozens of times thicker than that of electro-galvanizing and the corrosion resistant performance of the former is dozens of times of that of the later.