Hot rolling

The starting material of the hot rolling steel strip is usually the slab, especially the continuous casting base. And they are put into the roughing mill group and finishing mill group directly at the proper temperature. Hot rolled metals generally have little directionality in their mechanical properties and deformation induced residual stresses. And the steel strip is out of the recoiling machine, then it is processed according to the customer’s requests. Frankly, hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. And then it is processed to be the armor plates.

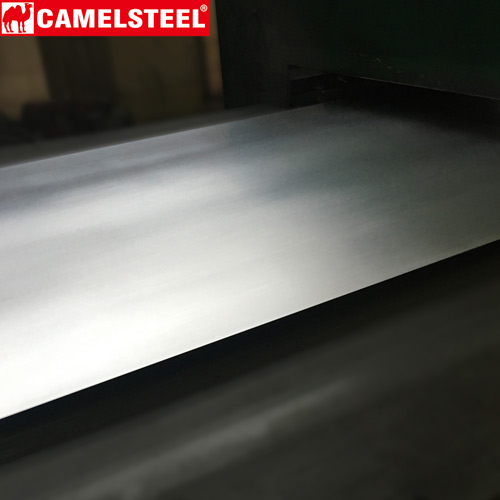

Cold rolling

The starting material is the hot rolling steel rolls. Then it removes the oxide skin by acid picking and produces the full hard coil. The continuous cold deformation makes cold hardening, which enhances the strength and hardness, as well as descends the ductile number. The full hard coil could be the material of the hot galvanization due to its annealed wire. The general weight of the full hard coil is between 6 t to 13.5 t. And its inner diameter is 610 mm.

Product features

Without the annealing treatment, its hardness is very great ( the HRB is over 90) and the machining property is very bad. Due to it, people could bend it less than 90 degree.

Frankly, the hot rolling steel roll is the material of cold rolling. And the process is hot rolling, acid picking and cold rolling.

Cold rolling occurs with the metal below its recrystallization temperature (usually at room temperature). Although the temperature rises during the process, it is called cold rolling. Because of the bad hardness and great hardness, it needs the annealing treatment to recover the mechanical property. And the one without annealing treatment is called the full hard coil. The full hard coil is used to produce those without bending or extruding.

To sum up, cold rolling occurs with the metal below its recrystallization temperature (usually at room temperature) and the material is the hot rolling steel plate.

Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. And then it is processed to be the armor plate.